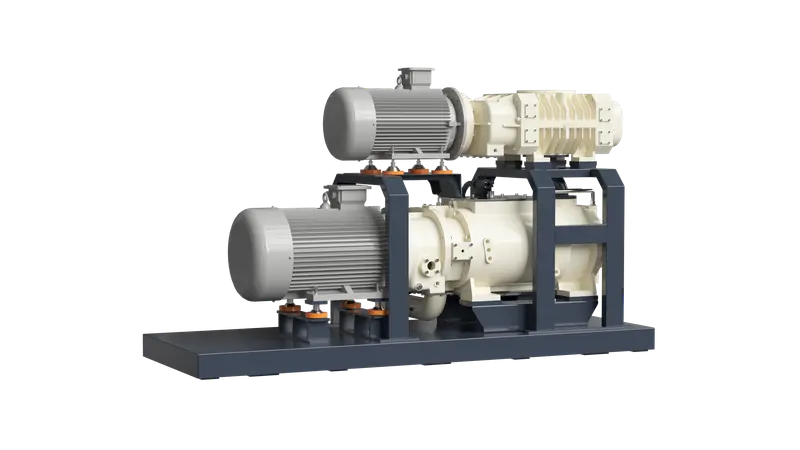

SDRV Series Screw Vacuum Pump

24/7 reliable operation with up to 50% energy savings in demanding industrial environments.

Explore SDRV Vacuum Pump Technology

Click on the interactive hotspots to discover the advanced engineering and components that make SDRV pumps industry-leading solutions.

Why Choose SDRV Screw Vacuum Pump?

Traditional vacuum pumps struggle with demanding industrial applications. SDRV's breakthrough technology solves critical operational challenges.

High Energy Consumption Crisis

Traditional liquid ring pumps consume excessive power

Traditional Pumps

- ✕ High power consumption

- ✕ $200,000+ annual electricity costs

- ✕ Inefficient energy conversion

SDRV Solution

- ✓ Advanced screw technology

- ✓ ROI within 24 months

- ✓ Sustainable operation

Corrosive Gas Damage

Chemical processes destroy conventional pump components

Conventional Pumps

- ✕ Frequent component failure

- ✕ Corrosive gas and water damage

- ✕ Wastewater costs exceed $5,000

SDRV Innovation

- ✓ Patented anti-corrosion technology

- ✓ Premium alloy materials

- ✓ Fills international market gap

Frequent Maintenance Downtime

Complex maintenance causes costly production interruptions

Standard Pumps

- ✕ Monthly maintenance required

- ✕ Complex disassembly process

- ✕ 24-48 hours downtime per service

SDRV Design

- ✓ Quarterly maintenance cycles

- ✓ 2-4 hours service time

- ✓ Simplified component access

Proven Performance Metrics

Ready to solve your vacuum pump challenges? Get a customized technical proposal based on your specific operational requirements.

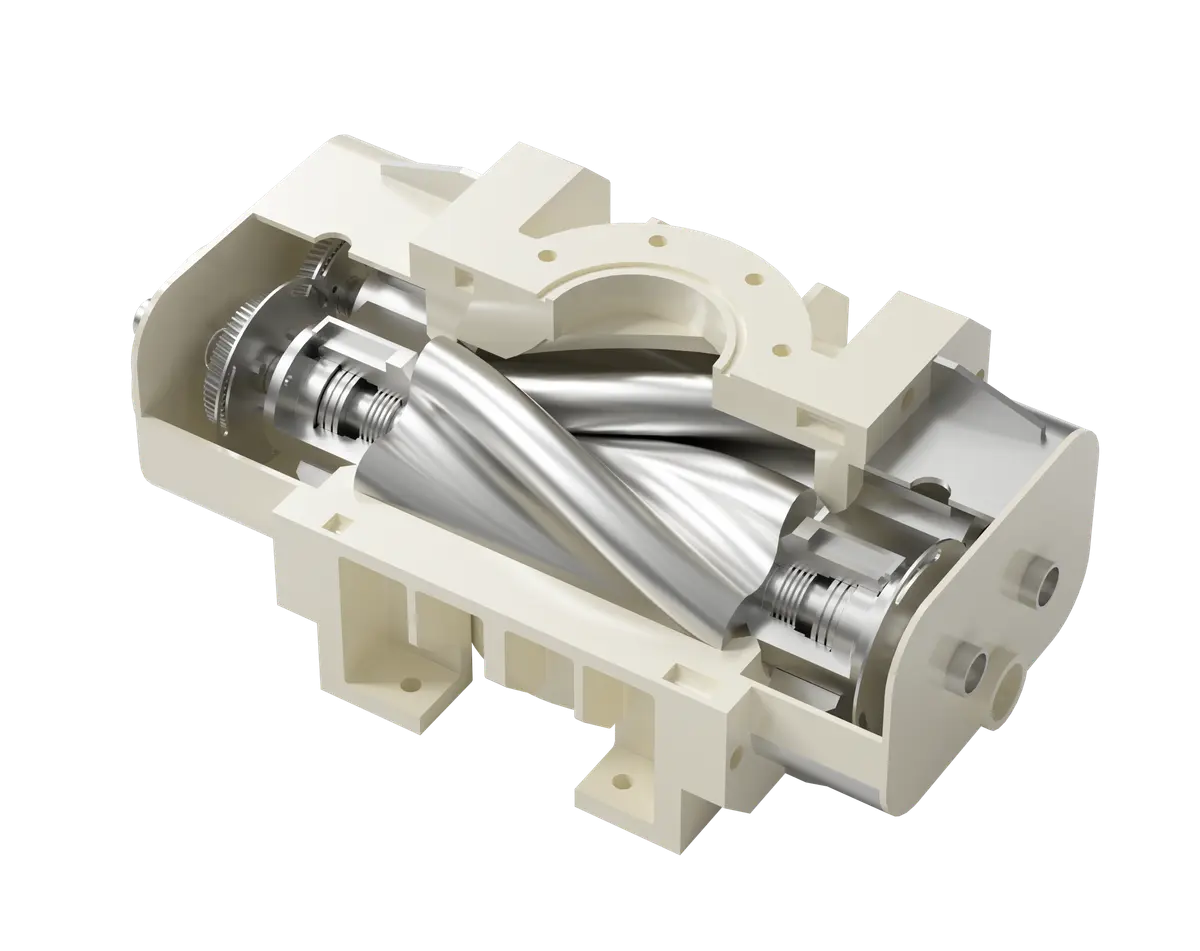

Engineered with Patented Screw Technology

Advanced screw technology delivering superior performance through innovative engineering and precision manufacturing. Our patented designs achieve 25-50% energy savings compared to traditional systems.

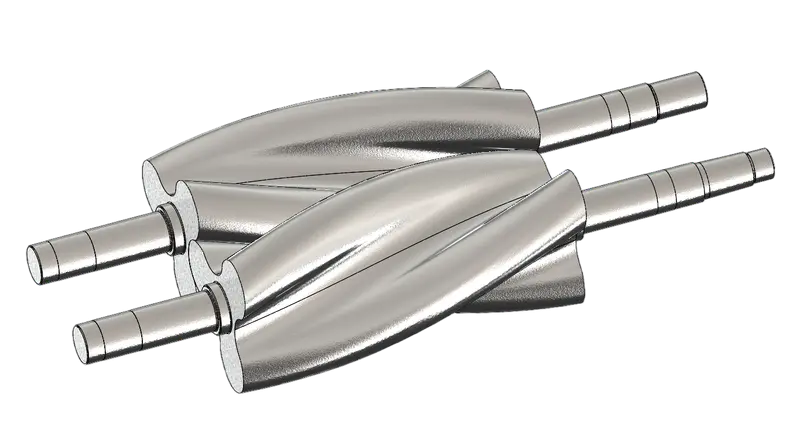

Optimized Symmetric Screw Profile

Advanced tri-lobe screw profile completes multiple suction and exhaust cycles per rotation, maximizing volumetric efficiency and minimizing gas leakage.

-

Higher working efficiency through optimized compression cycles

-

Extended rotor sealing angle reduces internal leakage

-

15% higher volumetric efficiency than traditional Roots

Patented Asymmetric Profile Technology

Proprietary multi-segment arc patent profile with smooth transitions, one-piece molding, and shortened contact lines that reduces power loss from internal leakage.

-

25-50% energy savings vs traditional Roots or liquid ring pumps

-

Optimized 5:7 profile for pressures above 20,000 Pa

-

Significantly reduced backflow for enhanced efficiency

Tailored Profile Engineering

Custom-engineered profiles designed by international experts and PhD-level engineers to meet specific industrial and laboratory requirements.

-

Bespoke profile designs for unique operating conditions

-

Optimized for various industrial and laboratory environments

-

Cost-effective despite complex manufacturing requirements

Intelligent Centralized Control

Advanced IoT-enabled control system with comprehensive monitoring, data logging, and remote operation capabilities for unmanned operation.

-

Real-time mobile app control and monitoring

-

Comprehensive data logging with fault diagnosis

-

RS485, Ethernet, MODBUS protocol support

-

Enables fully unmanned operation

Lower Total Cost of Ownership

Comprehensive analysis demonstrating SDRV's superior economic value through reduced energy consumption, extended service life, and minimized maintenance requirements.

Technology Comparison

← Scroll table horizontally →

| Comparison Item | Magnetic Levitation Centrifugal | SDRV Screw Technology |

|---|---|---|

| Material Quality | Cast Aluminum Alloy | 40CrMo High-Grade Steel |

| Design Service Life | 8 Years | 10+ Years |

| Operating Performance |

• High-speed wear issues • Performance degradation over time • High inlet filtration requirements |

• Superior material strength • Wear & corrosion resistant • Low-speed, contact-free operation |

| Rotor Efficiency |

• Poor material deformation resistance • Low rotor efficiency angle • Reduced overall efficiency |

• Optimized screw profile design • Internal compression capability High Efficiency |

| Air Quality Requirements | High Filtration Required | Low Air Quality Requirements |

Maintenance & Operation

← Scroll table horizontally →

| System Type | Maintenance Content & Cycle | Variable Frequency Range | Recommended Applications |

|---|---|---|---|

|

Magnetic Levitation

Vacuum Pump

|

Daily: Filter replacement (3-6 months) Major overhaul: 10+ years High maintenance cost ~70% of purchase price |

70%-100% |

• Stable operating conditions • Close to design parameters • Not suitable for >70KPa • Not suitable for frequent starts |

|

SDRV Screw

Vacuum Pump

|

Daily: Lubricant (2 years) + Filter (1 year) Major overhaul: Bearing seal assembly (5 years) Significantly lower maintenance costs |

25%-100% |

• Suitable for >80KPa applications • Wide variable frequency range • Ideal for frequent start-stop cycles |

Efficiency Analysis

← Scroll table horizontally →

| Pump Type | Ultimate Vacuum (kPa) |

Ultimate Flow (m³/h) |

Efficiency (%) |

Key Advantages & Notes |

|---|---|---|---|---|

| Water Ring Pump | 3.3 | 27,000 | 30-50% |

Simple structure, easy maintenance Low efficiency, unstable high pressure, cavity contamination |

| Single-Stage Roots | 50 | 24,000 | 40-60% |

Relatively stable pressure, higher efficiency than water ring Still low efficiency, low pressure, high noise |

| Double-Stage Roots | 30 | 15,000 | 60-80% |

Stable pressure, higher vacuum, much higher efficiency High noise, higher failure rate, high maintenance cost |

| Single-Stage Screw | 20 | 24,000 | 60-83% |

Unique forced cooling system, near-isothermal compression Enhanced equipment life 2-3 years Internal compression capability, compression ratio up to 10 |

|

BEST

SDRV Double-Stage Screw

|

10 | 24,000 | 70-95% |

SDRV's proprietary design achieves industry-leading efficiency Further improved ultimate vacuum and efficiency conversion Superior performance at competitive pricing |

Cost Optimization

← Scroll table horizontally →

| Pump Type | Actual Power (kW) |

Power Savings (kW) |

Energy Efficiency (%) |

|---|---|---|---|

|

Water Ring Pump

(37kW Reference)

|

37 | - | Baseline |

| SDRV Single-Stage Screw | 22 | 15 | 40% |

| Standard Single-Stage Screw | 26 | - | Reference |

| SDRV Single-Stage Optimized | 22 | 4 | 16% |

| Double-Stage Roots | 22 | - | Reference |

|

BEST

SDRV Double-Stage Screw

|

18.5 | 4.5 | 20% |

40%

Energy Savings

60%

Maintenance Reduction

25%

Uptime Improvement

Total Cost of Ownership Benefits

SDRV technology delivers measurable returns through energy savings, reduced maintenance, and extended service life

Calculate Your ROI

Get a personalized cost analysis and ROI projection for your specific application. Our engineers will provide detailed calculations showing your potential savings.

Versatile Solutions Across Industries

SDRV Screw Vacuum Pumps deliver reliable performance in demanding industrial applications, from pharmaceutical manufacturing to electronics production

What Our Customers Say

Discover how SDRV screw vacuum technology has transformed operations for industrial companies worldwide, delivering measurable results and exceptional reliability.

"After implementing SDRV's screw vacuum system in our drying operations, we achieved remarkable energy savings while maintaining the strict quality standards required for pharmaceutical manufacturing. The oil-free operation ensures product purity, and the reliable performance has significantly reduced our maintenance downtime. This investment has exceeded our expectations in every measurable metric."

Dr. Michael Hoffmann

Production Director, Major Pharmaceutical Manufacturer

Germany

"Our previous pumps suffered constant failures due to corrosive gases in our semiconductor processes. SDRV's anti-corrosion technology completely solved this problem. We've eliminated costly pump replacements and achieved stable production for over two years."

Tan Wei Lin

Engineering Manager, Electronics Manufacturer

Singapore

"We switched from liquid ring pumps to SDRV screw technology for our solvent recovery process. The energy savings alone justified the investment within the first year. The technical support team was exceptional during installation and commissioning."

James Mitchell

Plant Manager, Chemical Processing Inc.

Texas, USA

"For our freeze-drying operations, product purity is critical. SDRV's oil-free technology gives us complete confidence that our food products remain uncontaminated. The consistent vacuum levels have improved our product quality significantly."

Yamamoto Satoshi

Technical Director, Food Processing Co.

Osaka, Japan

"Operating in remote mining locations, equipment reliability is paramount. SDRV pumps have proven incredibly robust in harsh conditions. The extended maintenance intervals mean fewer site visits and lower operational costs for our vacuum filtration systems."

Steve O'Connor

Operations Superintendent, Mining Resources

Western Australia

"Our paper mill requires consistent vacuum for the dewatering process. After replacing our aging system with SDRV technology, we saw immediate improvements in paper quality and a significant reduction in energy consumption. The ROI has been outstanding."

Roberto Silva

Maintenance Manager, Pulp & Paper Industry

Sao Paulo, Brazil

Join hundreds of satisfied customers worldwide. Let us show you how SDRV technology can transform your operations.

Certified Excellence & Innovation Leadership

Our commitment to quality is validated by international certifications and protected by extensive intellectual property.

Pioneering anti-corrosion screw vacuum pump technology that fills an international market gap, establishing global leadership in corrosion-resistant vacuum solutions.

CE Certification

European Conformity Standards

ISO 9001:2015

Quality Management Systems

RoHS Compliant

Environmental Protection

ATEX Certified

Explosive Atmospheres

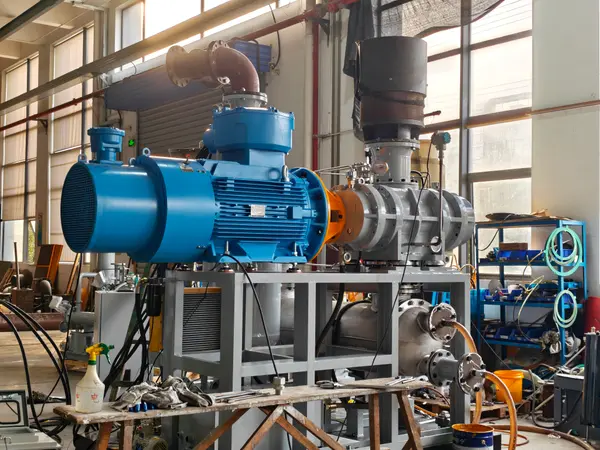

Our Production Facilities

Our factory is equipped with advanced machining and testing equipment to ensure precision and consistency in every screw vacuum pump and blower we produce.

Mazak CNC Machine Tools

High-precision machining for screw rotors and key components with exceptional accuracy and reliability.

Matsuura Five-Axis Processing

Multi-axis processing for complex parts, ensuring superior accuracy and manufacturing efficiency.

Hexagon Measuring Systems

Comprehensive inspection and measurement systems for strict quality control standards.

Assembly & Testing Lines

Strict assembly procedures and comprehensive performance testing before delivery.

From machining to final inspection, every step is carefully controlled to maintain product reliability and stability.

Swipe to explore

Complete Technical Datasheet

Comprehensive specifications for the SDRV Energy-Efficient Vacuum Pump Series

SDRV Energy-Efficient Vacuum Pump Series

All models feature oil-free operation and variable frequency drive

| Specification | Unit | SDRV 860-I | SDRV 1900-I | SDRV 3400-I | SDRV 6000-I | SDRV 8300-I | SDRV 10000-I | SDRV 12000-I |

|---|---|---|---|---|---|---|---|---|

| Flow Rate | m³/hr | 860 | 1,890 | 3,338 | 5,940 | 8,240 | 9,966 | 11,530 |

| Ultimate Pressure | mbar | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| Torr | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |

| Pa | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | |

| Motor Power | kW | 15 | 30 | 55 | 90 | 132 | 160 | 185 |

| Frequency | Hz | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 |

| Voltage | V | 220-440 | 220-440 | 220-440 | 220-440 | 220-440 | 220-440 | 220-440 |

| Inlet Port | mm | 100 | 150 | 200 | 250 | 300 | 300 | 400 |

| Outlet Port | mm | 100 | 150 | 200 | 250 | 300 | 300 | 400 |

| Noise Level | dB(A) | <80 | <80 | <80 | <80 | <85 | <85 | <85 |

| Dimensions (L×W×H) | mm | 1600×1060×1350 | 2150×1250×1740 | 2850×1650×1790 | 2850×1650×1790 | 3100×1750×2010 | 3100×1750×2010 | 3700×1750×2010 |

| Weight | kg | 850 | 1,450 | 2,200 | 3,100 | 4,200 | 4,800 | 5,500 |

Highlighted column: Recommended model for medium-scale applications

Specifications subject to change without notice. Contact us for detailed documentation.

Scroll horizontally to view all models

Key Performance Specifications

Industry-leading specifications across the complete SDRV vacuum pump series

Documentation & Customization

Access comprehensive technical resources and explore tailored solutions for your specific applications

Detailed Technical Documentation

Download comprehensive PDF datasheet with detailed specifications, performance curves, installation guidelines, and maintenance procedures.

Customization Services

Tailored solutions for specific applications with custom alloy materials, coatings, and control systems.

-

Custom alloy materials for specific applications

-

Enhanced anti-corrosion coating systems

-

Custom control and monitoring systems

-

Alloy materials customized for customer's working gas conditions

-

Modified port configurations and sizes