Our Factory

Professional Vacuum Technology Manufacturing

China screw vacuum pump & blower manufacturing factory, offering reliable products and customized solutions.

Advanced precision manufacturing with 25+ patents, delivering oil-free vacuum technology for global industrial applications since 2016.

25+ Patents

Independent R&D with breakthrough innovations in oil-free vacuum technology.

Advanced Equipment

Mazak, Matsuura, Hexagon precision manufacturing systems for superior quality.

ISO-Certified Quality

Strict quality control systems ensuring stable and reliable performance standards.

Flexible Customization

Tailored solutions designed for different industries and specialized processes.

25+ Patents

Independent R&D with breakthrough innovations.

Advanced Equipment

Mazak, Matsuura, Hexagon precision manufacturing.

ISO-Certified Quality

Strict quality control, stable & reliable performance.

Flexible Customization

Tailored solutions for different industries & processes.

Product Gallery

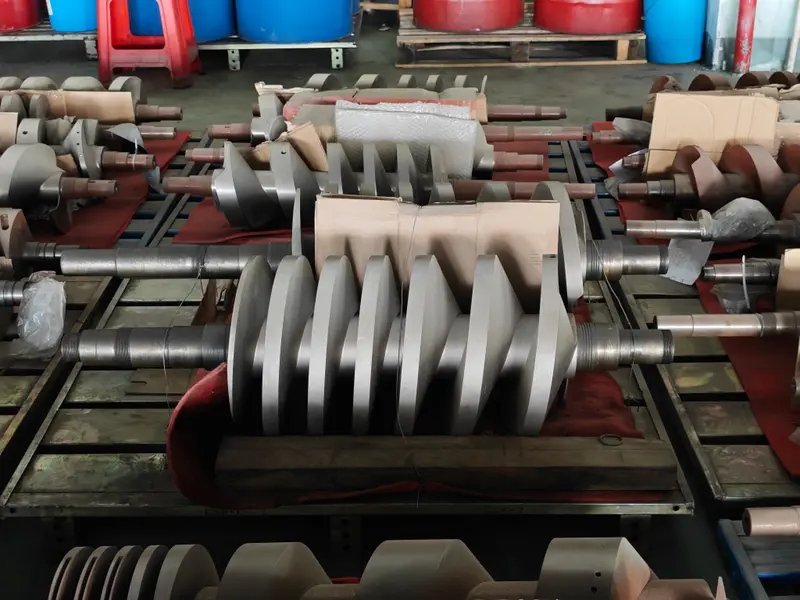

Our Production Facilities

Our factory is equipped with advanced machining and testing equipment to ensure precision and consistency in every screw vacuum pump and blower we produce.

Mazak CNC Machine Tools

High-precision machining for screw rotors and key components with exceptional accuracy and reliability.

Matsuura Five-Axis Processing

Multi-axis processing for complex parts, ensuring superior accuracy and manufacturing efficiency.

Hexagon Measuring Systems

Comprehensive inspection and measurement systems for strict quality control standards.

Assembly & Testing Lines

Strict assembly procedures and comprehensive performance testing before delivery.

From machining to final inspection, every step is carefully controlled to maintain product reliability and stability.

Our R&D Team

Our dedicated R&D team focuses on screw technology innovation and customized vacuum solutions. With more than 25 patented technologies and deep industry know-how, we work closely with customers to develop equipment tailored to their specific processes and requirements.

Core Manufacturing Process

Every screw vacuum pump and blower undergoes a rigorous manufacturing process, from raw material machining to final inspection. Each step is carefully controlled to ensure precision, stability, and long-term reliability.

Screw Rotor Machining

High-precision rotor processing forms the foundation of performance and efficiency using advanced CNC technology.

Component Assembly

Skilled technicians assemble key parts with strict adherence to process standards and quality protocols.

Quality Inspection

Each component undergoes dimensional and performance checks using advanced measuring systems and testing equipment.

Final Testing

Complete system testing ensures stable operation and compliance with customer requirements before delivery.

Through this complete workflow, we guarantee consistent quality and reliable operation for every delivered unit.

Quality Control Process

We apply strict multi-stage quality control to ensure each screw vacuum pump and blower delivers stable performance, energy efficiency, and long service life.

Material & Supplier Verification

Raw materials undergo chemical composition analysis and hardness testing. Critical outsourced parts are verified against supplier certificates.

Machining Accuracy Inspection

Precision measurement of screw rotors, housings, and shafts with Hexagon coordinate measuring systems and surface roughness checks.

Assembly Stage Quality Control

Rotor clearance, sealing fit, and lubrication system integrity checks. Dynamic balance testing to minimize vibration.

Performance Testing

Subsystem testing of vacuum chamber, oil circuit, and control unit. Noise level and energy consumption assessment.

Factory Acceptance Test

Full-load vacuum performance test under simulated conditions. Continuous operation run-in and documentation before delivery.

Only products that pass all five stages are approved for shipment, ensuring consistent quality and dependable operation for industrial applications.

Versatile Solutions Across Industries

KZB Screw Vacuum Pumps deliver reliable performance in demanding industrial applications, from pharmaceutical manufacturing to electronics production

Pharmaceutical

- Vacuum Drying → API crystallization and solvent removal

- Distillation → Pharmaceutical grade purification processes

- Sterilization → Steam sterilization and degassing systems

Chemical Processing

- Solvent Recovery → Efficient organic solvent reclamation

- Vacuum Distillation → High-purity chemical separation

- Degassing → Removal of dissolved gases from liquids

Electronics

- Photovoltaic → Silicon ingot pulling, component packaging

- Lithium Battery → Drying, injection, packaging processes

- Semiconductor → Electromagnetic sheet printing applications

General Manufacturing

- Heat Treatment → Vacuum quenching applications

- Food Preservation → Freeze drying processes

- Vacuum Suction → CNC, woodworking, printing applications

Customer Success Stories

Trusted by industrial companies worldwide

"Our KZB-100 has been running continuously for 18 months in our pharmaceutical drying process. The oil-free operation is crucial for our API production, and we've achieved 99.9% uptime. The energy savings compared to our previous system are remarkable - 30% reduction in power consumption."

Dr. Sarah Johnson

Production Manager, Pharmaceutical Manufacturing

"We installed three TW-300 compressors for our lithium battery production line. The precision and stability are exceptional - we're achieving vacuum levels of 0.1 mbar consistently. Shichang's technical support team helped us optimize the entire system. Production efficiency increased by 25%."

Michael Chen

Engineering Director, Electronics Manufacturing

"The KZC-200 anti-corrosive series handles our aggressive chemical processes perfectly. After two years of operation in harsh conditions, maintenance costs are 40% lower than our previous equipment. The investment has paid for itself through reduced downtime and energy savings."

David Rodriguez

Plant Operations Manager, Chemical Processing

Our Production Team

Behind every screw vacuum pump and blower is a skilled production team. From machining and assembly to testing and inspection, our technicians work with precision and dedication to ensure every unit meets quality standards.

Our production team consists of experienced technicians, quality specialists, and skilled machinists who work together to manufacture exceptional vacuum equipment.

Experience Our Quality

See how our skilled production team can deliver the precision vacuum equipment your industrial processes demand. From custom configurations to standard models, we're ready to support your project requirements.